Continual Improvement ISO: How ISO Improves Quality, Security, and Delivery Processes

Continual improvement ISO represents a fundamental shift from viewing certification as a finish line to embracing it as a starting point. Too many organizations celebrate their ISO certification and then file the documentation away. They miss the transformative power of ongoing optimization. Understanding what is ISO helps organizations recognize that these frameworks aren’t static requirements. They’re dynamic systems designed for continuous enhancement.

This article explores how continual improvement transforms three critical business areas. You’ll discover specific process cycles, real-world examples, and practical metrics. Most importantly, you’ll understand how quality consistency, security risk reduction, and operational delivery improvements interconnect through systematic enhancement. Let’s examine how organizations turn ISO frameworks into engines of sustained progress.

- 1) Understanding Continual Improvement in ISO Standards

- 2) ISO Continual Improvement for Quality Management

- 3) ISO Continual Improvement for Security Processes

- 4) ISO Continual Improvement and Operational Delivery

- 5) Integrating Continual Improvement ISO Across Quality, Security, and Delivery

- 6) Getting Started with Continual Improvement ISO

- 7) Conclusion

Understanding Continual Improvement in ISO Standards

Organizations often misunderstand what ISO continual improvement process actually entails. It’s not about perfection or massive overhauls. Instead, it focuses on systematic, incremental enhancements that accumulate over time. Each improvement builds on the previous one, creating upward momentum.

What Continual Improvement ISO Really Means

Continual improvement ISO differs fundamentally from basic compliance. Compliance means meeting minimum standards at a point in time. Meanwhile, improvement means getting better every month, every quarter, and every year. The ISO framework provides structure for this ongoing journey.

Think of ISO certification as obtaining a driver’s license. The license proves you meet minimum safety standards. However, experienced drivers continuously improve their skills through practice and feedback. Similarly, ISO-certified organizations should constantly refine their processes. They identify weaknesses, implement solutions, and verify results.

This philosophy transforms ISO from a burden into a business advantage. Rather than viewing audits as threats, organizations see them as opportunities. Each audit reveals areas for enhancement and each corrective action strengthens operations. Hence, the cycle never stops, and neither do the benefits.

The ISO Continual Improvement Process

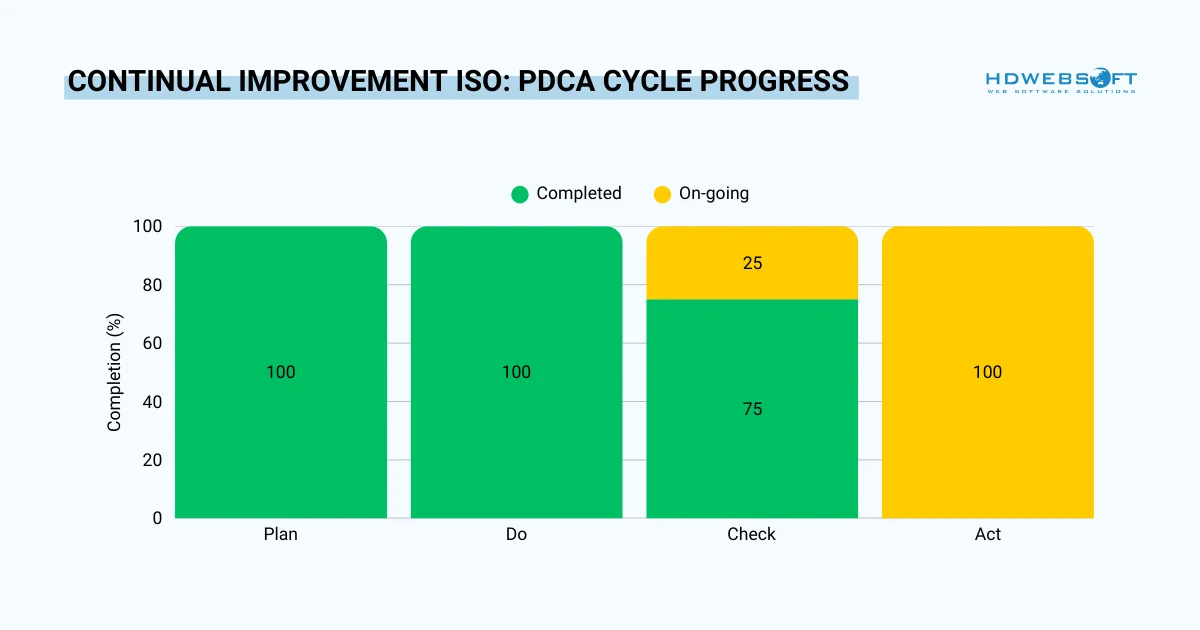

The Plan-Do-Check-Act (PDCA) cycle forms the backbone of the continual improvement ISO process. This four-stage approach turns reactive problem-solving into proactive optimization. Understanding each phase helps organizations maximize their improvement efforts.

Plan

It involves identifying opportunities through data analysis and risk assessment. Teams examine metrics, audit findings, and customer feedback, then pinpoint specific areas where processes fall short of goals. After that, they develop targeted improvement initiatives with clear objectives and timelines.

Do

This means implementing changes in controlled environments, as in organizations test improvements on a small scale first. This approach minimizes risk while gathering valuable data. Notably, pilot programs reveal unexpected challenges before full-scale deployment, while documentation captures lessons learned for future reference.

Check

This stage requires monitoring results using KPIs and performance indicators as teams compare actual outcomes against predicted improvements. They also identify gaps between expectations and reality. Statistical analysis helps separate signals from noise and regular reviews ensure improvements stick rather than fade.

Act

The last phase in continual improvement ISO process standardizes successful changes and addresses remaining gaps. Effective improvements become new baselines for operations. Teams update procedures, train staff, and communicate new standards. The cycle then restarts, targeting the next improvement opportunity. In all, this rhythm creates a culture of continuous enhancement.

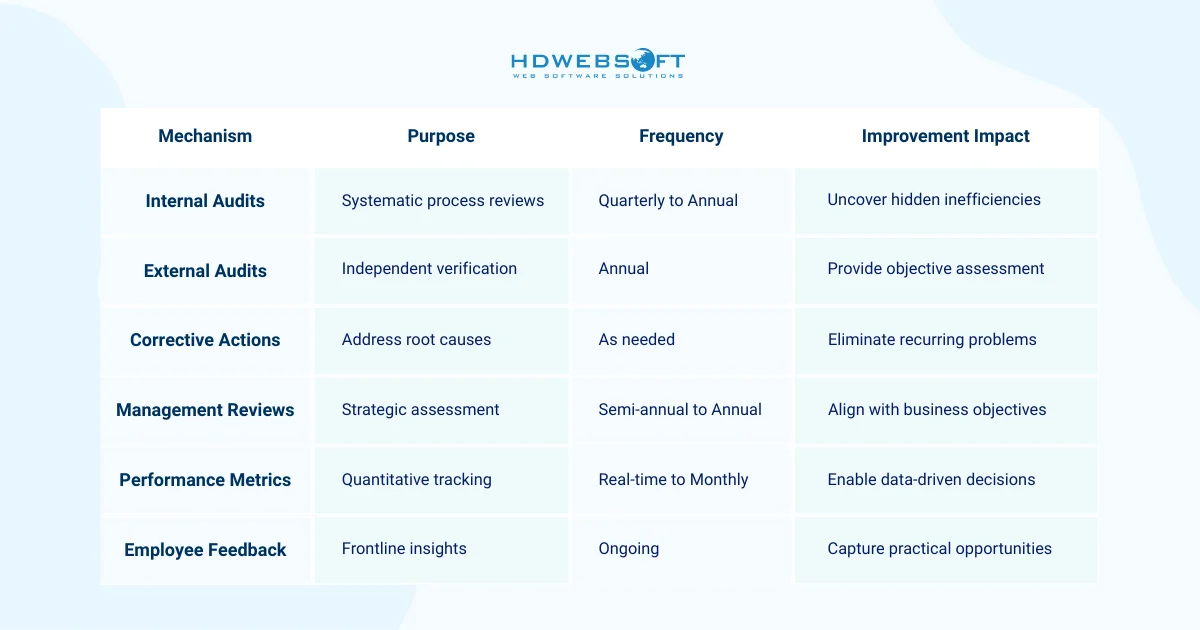

Core Continual Improvement ISO Mechanisms

Beyond PDCA, several specific mechanisms drive ongoing improvement within ISO frameworks. Each plays a distinct role in identifying and implementing enhancements. These mechanisms work together to create a comprehensive improvement ecosystem as they form a robust system for sustained enhancement.

ISO Continual Improvement for Quality Management

Quality management represents the most mature application of ISO continual improvement for quality management principles. ISO 9001 has refined these approaches over decades, creating frameworks that drive measurable quality gains.

How ISO 9001 Embeds Continual Improvement

ISO 9001 doesn’t just recommend improvement—it requires it. Clause 10.3 specifically mandates that organizations continually improve the suitability, adequacy, and effectiveness of their quality management system.

Risk-based thinking permeates modern continual improvement ISO 9001 standards. Organizations must identify potential quality issues before they occur. They assess risks at the process level and implement preventive controls. This proactive approach replaces the old reactive model of waiting for failures.

Moreover, customer satisfaction serves as a primary driver for quality improvements. Organizations systematically collect and analyze customer feedback. They track metrics like Net Promoter Score, complaint rates, and repeat business.

Quality Process Improvement Examples

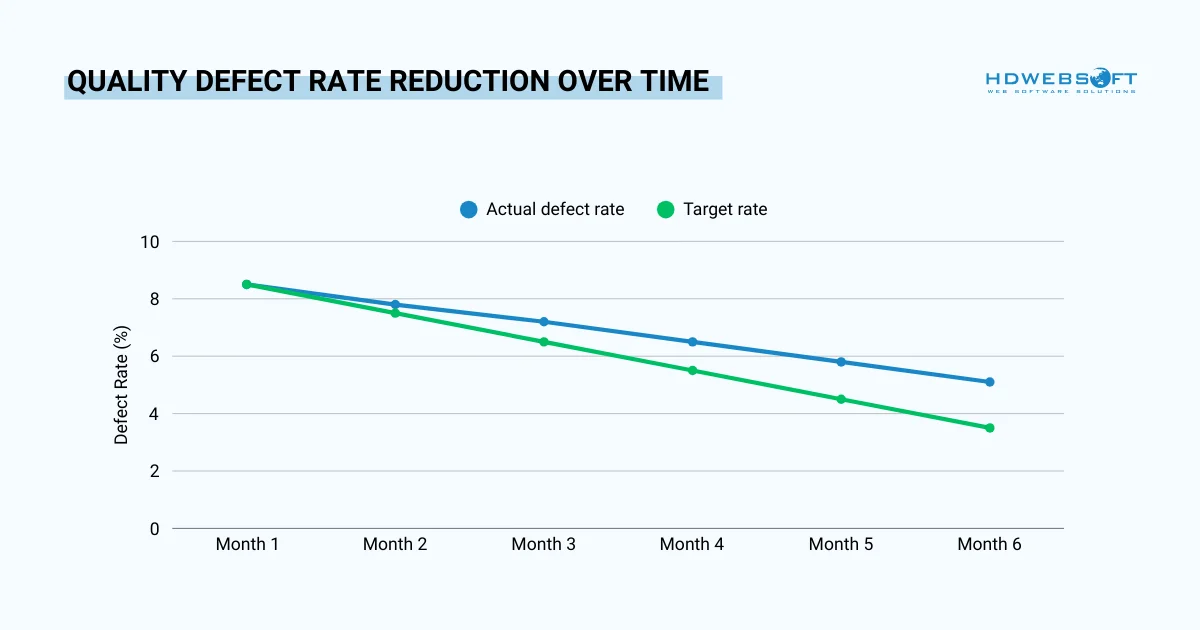

Manufacturing Defect Reduction

The manufacturing environments demonstrate ISO continual improvement for quality management particularly well. Consider a mid-sized automotive parts supplier struggling with defect rates. With that in mind, initial audits revealed patterns in material inconsistencies from specific suppliers.

The organization launched a structured CAPA process. Specifically, they implemented incoming material inspections and worked with suppliers on process improvements. Monthly metrics tracked defect rates by supplier and material type. As a result, within six months, defects dropped 40 percent.

Service Delivery Consistency

In fact, service organizations benefit equally from continual improvement ISO for quality management approaches. A software development company analyzed customer complaints and discovered communication gaps during project kickoffs. However, clients felt confused about timelines and deliverables.

The team revised their onboarding documentation and created structured kickoff meetings. They implemented a client satisfaction checkpoint at day 30 of each engagement. Consequently, Net Promoter Scores improved from 32 to 68 within one year.

Key Quality Metrics

Effective quality improvement requires robust measurement:

- Defect rates provide immediate feedback on process performance.

- Tracking these rates over time reveals whether improvements are working.

- Segmenting by product line, shift, or operator identifies specific problem areas.

COPQ

Cost of poor quality quantifies the financial impact of quality issues. This includes scrap, rework, warranty claims, and customer returns. As organizations improve processes, COPQ decreases. Hence, the savings often exceed the cost of quality management systems themselves.

Client Satisfaction

Customer satisfaction scores close the feedback loop in continual improvement ISO process. They validate whether internal quality metrics actually matter to customers. As a matter of fact, the combination of internal and external metrics drives meaningful progress.

ISO Continual Improvement for Security Processes

Security threats evolve constantly, making ISO continual improvement for security processes essential rather than optional. Yesterday’s adequate controls may be insufficient tomorrow. Therefore, organizations must continuously assess, adapt, and enhance their security postures to stay ahead of emerging risks.

ISO 27001 and Adaptive Security Management

As a matter of fact, ISO 27001 treats security as an ongoing cycle of risk assessment and control refinement. The standard requires regular reviews of information security risks. That’s why businesses must evaluate whether existing controls remain effective against current threats. This prevents security programs from becoming outdated artifacts.

Continuous Refinement of Security Controls

Annex A controls provide a comprehensive security framework covering 93 specific controls. However, implementation isn’t one-and-done. Organizations should regularly reassess which controls apply to their current risk profile. This is because new technologies, business models, or threat vectors may require additional controls. The continual improvement ISO standards for security processes approach ensures controls evolve with the organization.

Furthermore, risk treatment plans undergo continuous refinement. As organizations implement controls and gain experience, they identify gaps and inefficiencies. Perhaps a control proves too restrictive for business operations, or maybe a risk requires additional mitigation. Thus, the cycle of assessment, treatment, monitoring, and review keeps security measures practical and effective.

Security Process Enhancement Examples

Access Control Optimization

A financial services company discovered access control weaknesses during their internal audit. User permissions had accumulated over time; the classic “privilege creep” problem. Employees who changed roles retained access from previous positions.

As a practical action, the organization implemented quarterly access reviews as a corrective action. Each department manager certified that their team members had appropriate permissions. Within three months, they revoked over 300 unnecessary access grants, resulting in the potential for data exposure decreased dramatically.

Incident Response Improvement

Another organization used the continual improvement ISO standards for security processes to enhance incident response. Their initial security event analysis revealed concerning detection delays. On average, potential incidents took six hours to reach the security team.

To solve this, they implemented a SIEM (Security Information and Event Management) system with automated alerting. The system correlated events across multiple sources and flagged suspicious patterns immediately. Consequently, mean time to detect dropped from six hours to 15 minutes.

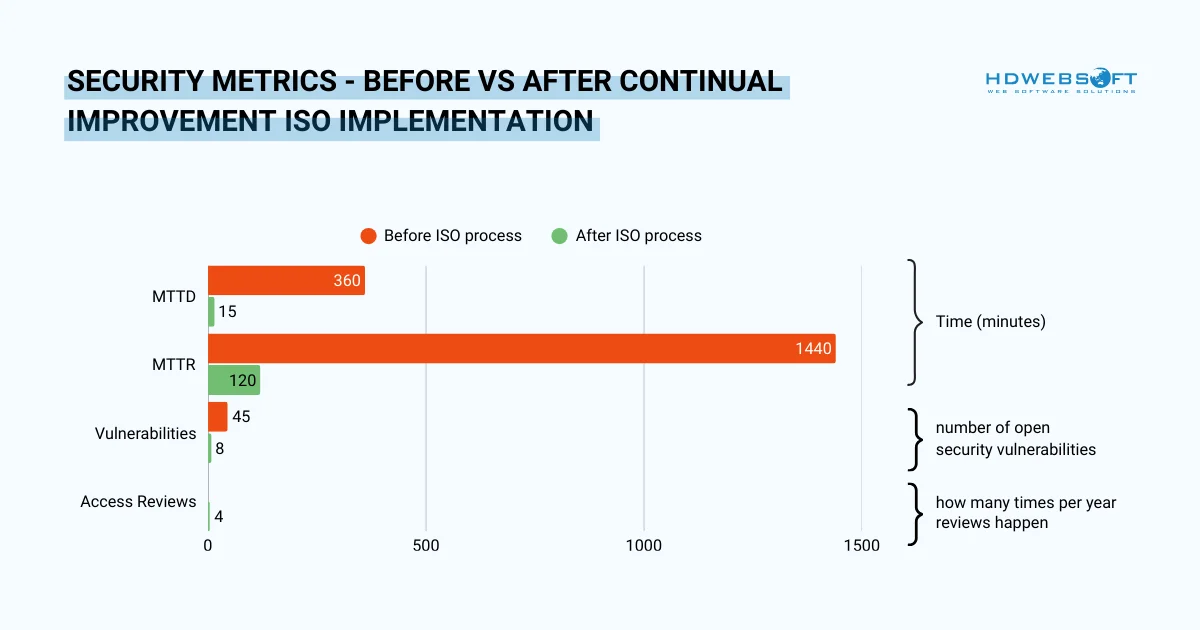

Security Metrics for Risk Reduction

Measuring Detection and Response Effectiveness

Mean time to detect (MTTD) and mean time to respond (MTTR) are critical security metrics. Together, they measure how quickly organizations identify and address security events. The ISO continual improvement process focuses on reducing both metrics over time. In essence, faster detection and response minimize potential damage.

Tracking Remediation Performance Over Time

Vulnerability remediation rates track how quickly organizations patch identified weaknesses. In the continual improvement ISO process, industry benchmarks suggest critical vulnerabilities should be patched within 24 hours. Concurrently, high-severity issues within seven days.

Moreover, regular measurement reveals whether vulnerability management processes are adequate. Trends also indicate whether the organization is improving or regressing.

Evaluating Near-Misses and Security Outcomes

Security incidents versus near-misses provide valuable insight. If you’re not familiar with the term, near-misses are events that could have become incidents but were caught in time. Thus, a high near-miss rate might seem concerning but actually indicates effective detection.

The goal is to maximize near-miss detection while minimizing actual incidents as this ratio demonstrates security program effectiveness.

Monitoring Control Gap Closure Progress

Compliance gap closure tracking monitors progress toward full control implementation. Organizations rarely achieve 100 percent compliance immediately. They prioritize gaps based on risk and resources. Tracking closure rates shows momentum and identifies stalled initiatives. Leadership can allocate resources to accelerate critical improvements.

ISO Continual Improvement and Operational Delivery

Continual improvement ISO and operational delivery create a powerful combination for business excellence. However, many organizations overlook how quality and security improvements directly accelerate delivery.

How Continual Improvement ISO Drives Delivery Excellence

Process standardization enables faster execution by reducing decision fatigue and variability. When teams follow proven procedures, they spend less time figuring out what to do. Hence, the predictability allows better planning and resource allocation.

Risk management prevents delivery delays by identifying and mitigating potential obstacles before they occur. Consider change management in IT operations since poorly planned changes cause outages and rollbacks. ISO-based change management processes assess risks, test thoroughly, and plan rollbacks.

Delivery Optimization Examples

Software Deployment Cycles

A software company struggled with lengthy deployment cycles and frequent rollbacks. Initial release cycles took two weeks and failed 30 percent of the time. Failures meant emergency fixes, overtime, and frustrated customers.

They implemented a continual improvement ISO-based change management process with clear gates and criteria. The team tracked metrics on deployment success rates and time to production. Within six months, release cycles shortened to one week with a 95 percent success rate.

Supply Chain Reliability

A manufacturing company faced unpredictable supplier delivery times. Lead times varied by up to 60 percent from the same supplier. This variability forced excess inventory and disrupted production schedules.

The organization launched a supplier audit program based on ISO quality principles. They assessed supplier processes, quality controls, and delivery capabilities. As a desirable result, lead time variability decreased by 60 percent within one year.

Delivery Performance Metrics

Reducing End-to-End Delivery Timelines

Cycle time measures how long work takes from start to finish. Lead time tracks the duration from customer request to delivery. Both metrics reveal efficiency opportunities. The continual improvement ISO process focuses on reducing both while maintaining quality.

Improving On-Time Delivery Performance

On-time delivery percentage indicates reliability and customer satisfaction. Simultaneously, missing delivery commitments damages relationships and reputation. Organizations tracking this metric often discover systemic issues in estimation, resource allocation, or process execution. All the while, addressing root causes improves the metric and business outcomes simultaneously.

Increasing Deployment and Release Success

The change in success rate applies particularly to IT operations and product development. What percentage of changes, deployments, or releases succeed without issues? High success rates indicate mature processes while low rates suggest inadequate risk management or testing. Tracking trends reveals whether improvement initiatives are working.

Optimizing Resource Utilization Sustainably

Resource utilization efficiency balances productivity with sustainability. Organizations can achieve high output through brute force and overtime. However, this approach isn’t sustainable. Efficient utilization means accomplishing more with the same resources through process improvement. Hence, continual improvement ISO for operational efficiency metrics like output per employee hour or projects per team member reveal efficiency trends.

Integrating Continual Improvement ISO Across Quality, Security, and Delivery

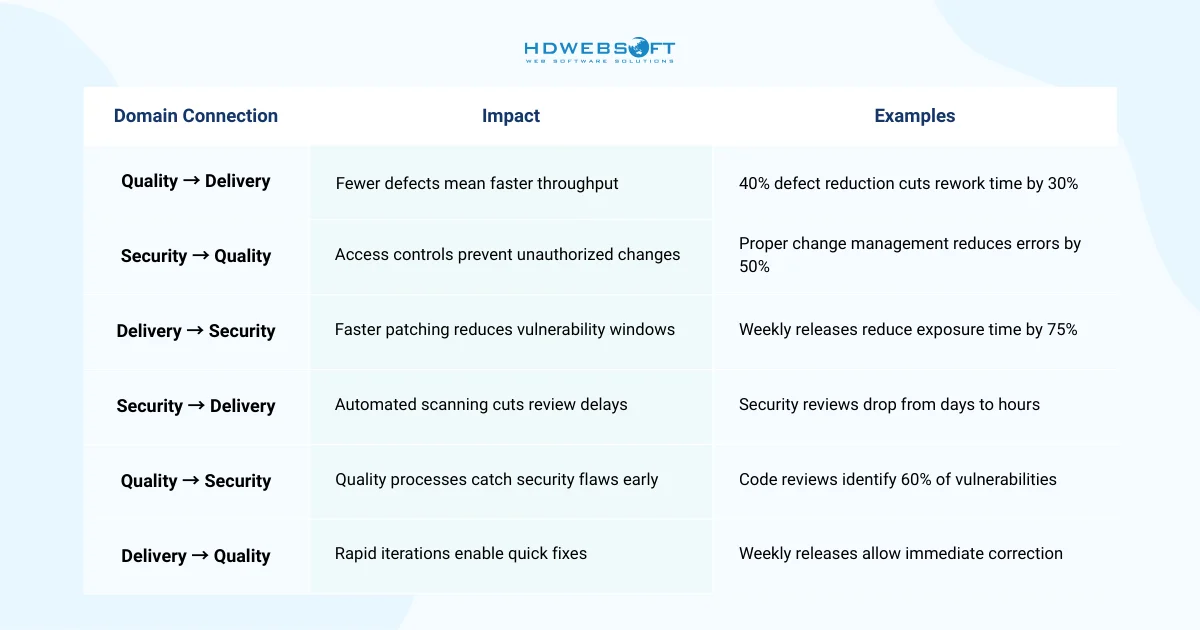

The true power of ISO standards for continual improvement emerges when organizations integrate efforts across all three domains. Quality, security, and delivery aren’t separate concerns; they’re interconnected systems. Improvements in one area create ripple effects throughout the organization.

Understanding the Interconnected Nature

Quality problems frequently create security vulnerabilities. Poor code quality leads to bugs that attackers exploit. Inadequate quality control in supplier management creates supply chain security risks. Not only that but the connection is pervasive across industries.

How Incidents Disrupt Delivery Flow

- Security incidents disrupt delivery schedules dramatically.

- A ransomware attack halts production.

- A data breach triggers emergency response and investigation.

- Security reviews delay product launches when conducted at the last minute.

- Integrating security into delivery processes prevents these disruptions.

- Security becomes an enabler rather than a bottleneck.

How Rushed Execution Erodes Quality

Poor delivery processes compromise quality through rushed work and inadequate testing, which is against continual improvement ISO processes. When organizations push to meet arbitrary deadlines, shortcuts happen: testing gets compressed, quality checks get skipped.

The result is predictable: defects reach customers. So, sustainable delivery velocity requires robust quality processes throughout the pipeline.

Building a Culture of Continuous Enhancement

Setting the Tone for Continual Improvement

Leadership commitment determines whether continual improvement succeeds or becomes paperwork. Leaders must visibly support improvement initiatives with time, resources, and attention. They should celebrate improvement successes and treat failures as learning opportunities since their behavior sets the tone for the entire organization.

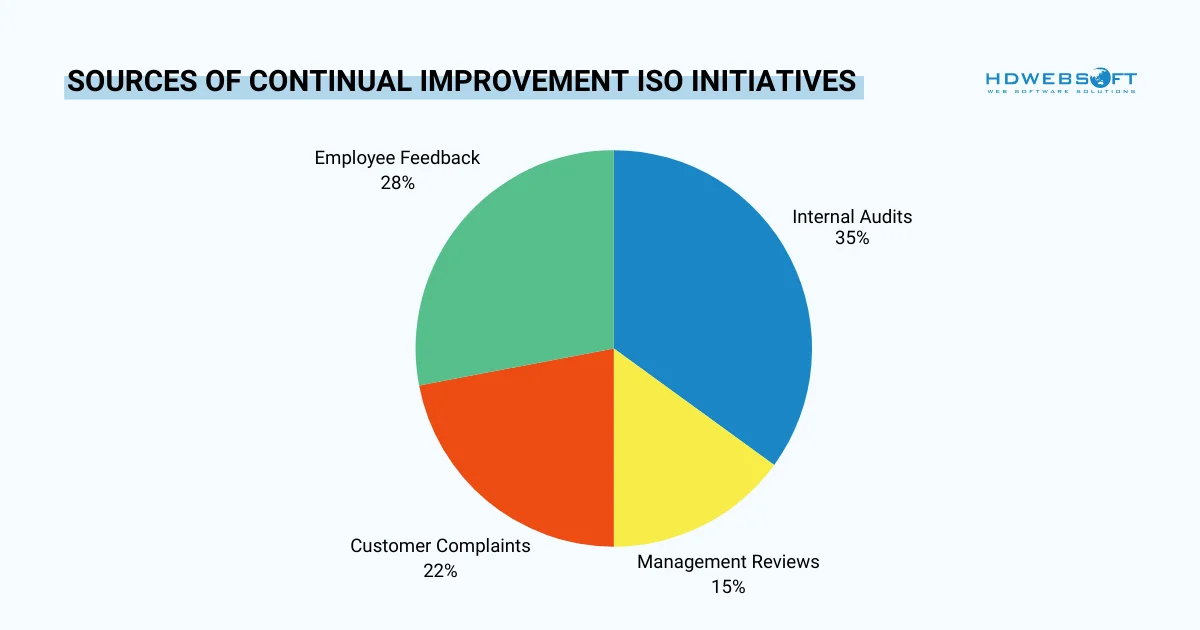

Enabling Frontline-Driven Improvements

Employee empowerment unlocks frontline improvement potential. Workers closest to processes see problems and opportunities that management misses. Organizations should create channels for employees to suggest improvements. More importantly, they should act on those suggestions and implement ideas that should be recognized and rewarded. This creates a virtuous cycle of engagement and improvement.

Breaking Silos Through Cross-Functional Teams

Cross-functional continual improvement ISO teams break down silos that inhibit progress. Quality, security, and operations teams often work independently. However, the best improvements require collaboration. Mixed teams bring diverse perspectives and expertise; they identify connections and opportunities that specialized teams overlook. Consequently, the whole becomes greater than the sum of parts.

Sustaining Progress Through Incremental Wins

Celebrating incremental wins maintains momentum and engagement. Not every improvement will be dramatic or transformative. Small wins matter too.

According to Gallup, doubling employees who strongly agree they received recognition recently could yield a ~9% productivity improvement and a ~22 % decrease in absenteeism and safety incidents. Notably, recognition doesn’t require large budgets as acknowledgment in team meetings or company newsletters often suffices. Momentum builds from consistent progress.

Getting Started with Continual Improvement ISO

Organizations ready to embrace continual improvement ISO need practical starting points. The journey begins with assessment and baseline establishment.

Immediate Action Steps

First and foremost, establish baseline metrics across quality, security, and delivery before implementing improvements. Document current defect rates, security incident frequency, and delivery timelines. These baselines provide objective reference points for measuring progress.

Next, set up regular management review meetings to maintain focus and momentum. Monthly or quarterly reviews should assess improvement progress and resource needs. Additionally, these reviews demonstrate leadership commitment to the entire organization.

Finally, create a simple CAPA tracking system to manage improvement initiatives. Spreadsheets work fine initially, and sophisticated software can come later. The system should track identified issues, root causes, planned actions, and responsible parties. Consequently, nothing falls through the cracks.

Sustaining Long-Term Success

Once initial steps are in place, invest consistently in training and awareness across the organization as part of continual improvement ISO process. People need to understand why improvement matters and how they contribute. Moreover, training shouldn’t be one-time during certification prep since it requires ongoing reinforcement.

In parallel, use technology to automate monitoring and free human attention for analysis. Manual data collection is tedious and error-prone. By contrast, automated systems capture metrics continuously and accurately, enabling faster response times.

Furthermore, conduct regular internal audits beyond certification requirements. Quarterly internal audits of different areas provide continuous feedback. As a result, they identify emerging issues before they become serious problems that require extensive remediation.

Conclusion

Continual improvement ISO transforms certification from a static achievement into a dynamic capability. ISO continual improvement for quality management, security processes, and operational delivery aren’t separate initiatives. They’re interconnected aspects of organizational excellence. The whole system improves together.

At HDWEBSOFT, we integrate ISO principles into our software development and delivery processes. Our commitment to continual improvement ensures that every project benefits from quality management practices, security controls, and optimized delivery cycles. Whether you’re building custom software or scaling your digital infrastructure, our ISO-aligned approach delivers consistent results. Partner with HDWEBSOFT, a company that treats excellence as a process, not a destination.