An oil and gas pressure monitoring system

This pressure monitoring system lets you see your entire oil and gas operation more clearly, respond to issues more quickly, and connects you to a world of savings in all working environments.An oil and gas pressure monitoring system

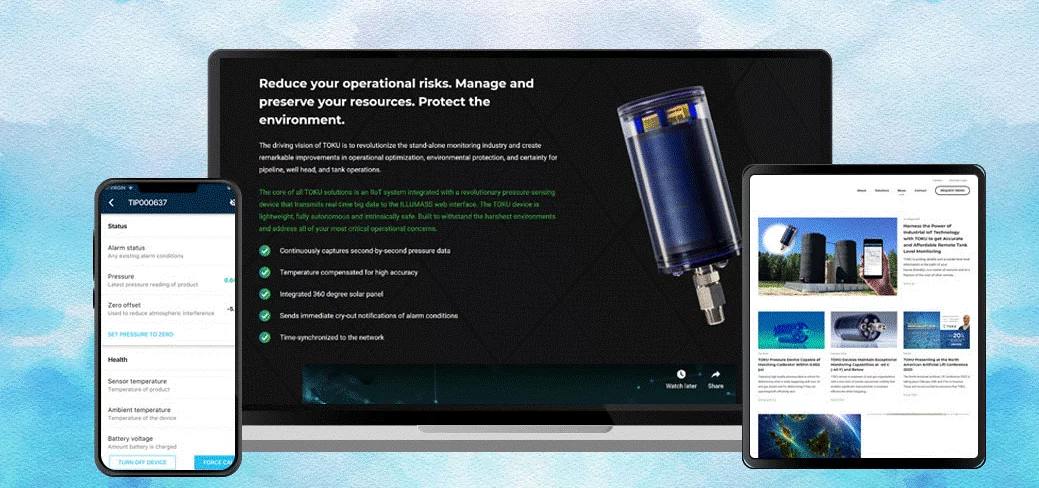

Reducing your operational risks. Managing and preserving your resources. Protect the environment.

The driving vision of the oil and gas pressure monitoring system is to revolutionize the stand-alone monitoring industry and create remarkable improvements in operational optimization, environmental protection, and certainty for the pipeline, wellhead, and tank operations.

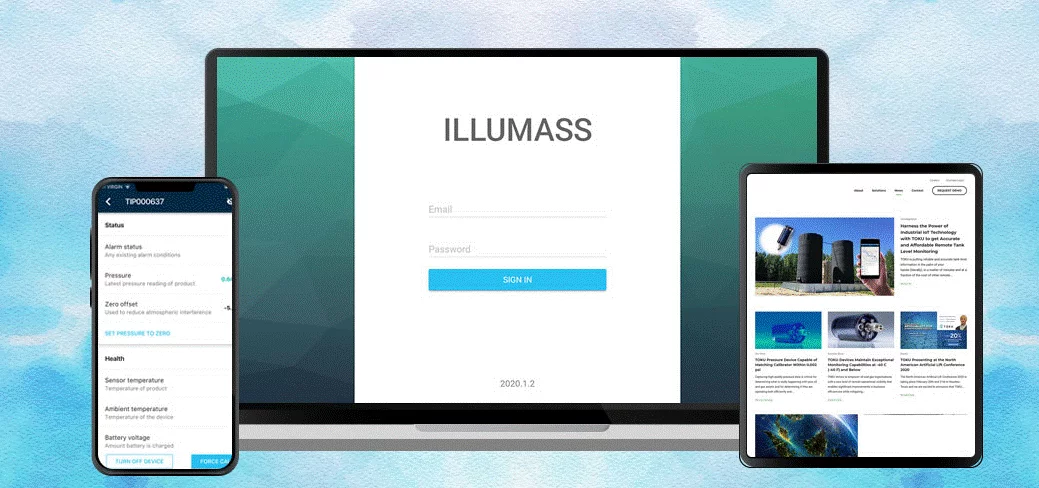

The core of all these solutions is an IIoT system integrated with a revolutionary pressure-sensing device that transmits real-time big data to the ILLUMASS web interface. The integrated device is lightweight, fully autonomous, and intrinsically safe. Built to withstand the harshest environments and address all of your most critical operational concerns.

Features

- Continuously capturing second-by-second pressure data.

- Temperature compensation for high accuracy.

- Integration 360-degree solar panel.

- Sending immediately cry-out notifications of alarm conditions.

- Time synchronization to the network.

With oil and gas pressure monitoring system, we can

- Detect weak plunger pump valves.

- Analyze operating conditions on pumping equipment.

- Immediately detect incorrect valve position.

- Monitor operating conditions on downhole pumps for run status, SPM, and pump efficiency.

- Continuously compare tubing and casing pressure on new drills.

- Monitor line pressure for Emergency Shutdown Device closure.

- Report on maximum wellhead injection pressure (MWHIP) for regulatory compliance.

- Compare to a Dead Weight, but with a web application attached.

Challenges

- This system has been built using the illumass SDK. That’s a real-time data transmission framework. So it’s harder to debug than using a Rest API Framework.

- This system requires a very high standard of testing including test automation.

- This system requires implementing many probability statistics algorithms.

- This system requires a very high standard of real-time data visualization.

Solutions

- We had to keep patient and step by step resolved the maths.

Why Choose HDWEBSOFT For Software Development

HDWEBSOFT is a trusted offshore software development company in Vietnam. We have implemented more than 300 projects and have been trusted by many businesses worldwide. Our developer has the expertise, knowledge, and experience to help companies drive digital transformation in the development stage. Want to learn more about why we’re the right choice? Contact us and we’ll be happy to provide further information.

Category

All, Angular.js, BI, Big Data, iOS, IoT, IoT & Utilities, Large-Scale, Map & Location Based, Mobile Apps, Node.js, Platform, React Native, Real Time, Tools & Utilities, Visualization, Web Apps